Infrastructure

Manufacturing

Quality Control Process

1

Visual Match

Granules checked for colour, size, and finish

2

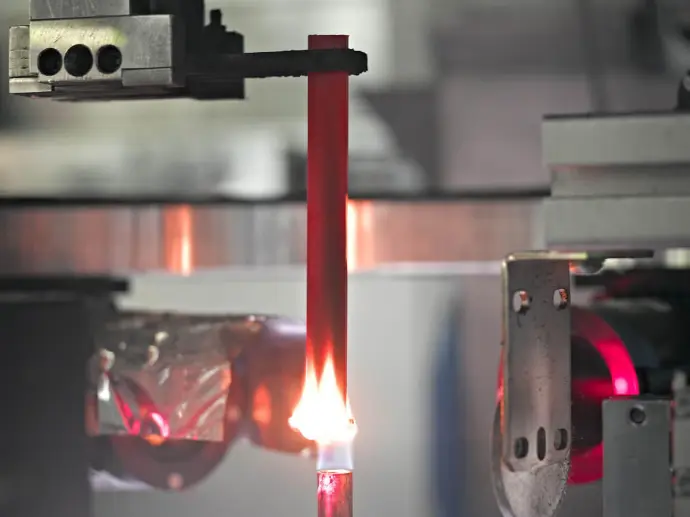

Application Simulation

Chips or film tested for dispersion and colour against standard

3

Property Test

MFI, FPV, CPG, Bulk Density, and Moisture Content

4

Traceability

Sample retained for future traceability

5

Batch Consistency

Every shipment includes CoA