Features

Prevents Screen Choking or Filament breakage

Achieve uninterrupted production with masterbatches engineered for superior dispersion. Our formulations prevent filter blocking and screen choking, ensuring a continuous extrusion process that minimizes downtime and eliminates costly filament breakage.

Prevents Denier Variation in Filament

Ensure consistent quality with low Filter Pressure Value (FPV) and stable melt flow. Our masterbatches guarantee uniform thickness across the entire filament length, eliminating denier variation and providing structural integrity.

Colour Masterbatches

Aangee offers a comprehensive range of colour masterbatches for PP Multifilament Yarn. We provide a vast selection of standard and custom shades to suit any application. Our custom shade development ensures perfect colour matching, delivering consistent, vibrant, and precise results.

Additive Masterbatches

Aangee offers a comprehensive range of additive masterbatches for PP Multifilament Yarn. Our advanced formulations ensure superior dispersion, consistent protection, improved durability, and optimized processing.

UV Resistant

Prevents material degradation caused by harmful sunlight exposure.

Softener

Enhances softness and prevents filamentation.

Antioxidant

Prevents thermal degradation and extends product lifespan.

Optical Brightener (OB)

Enhances brightness to deliver a clean, premium appearance.

Polymer Processing Aid (PPA)

Improves manufacturing runnability and ensures a smooth finish.

Why Aangee

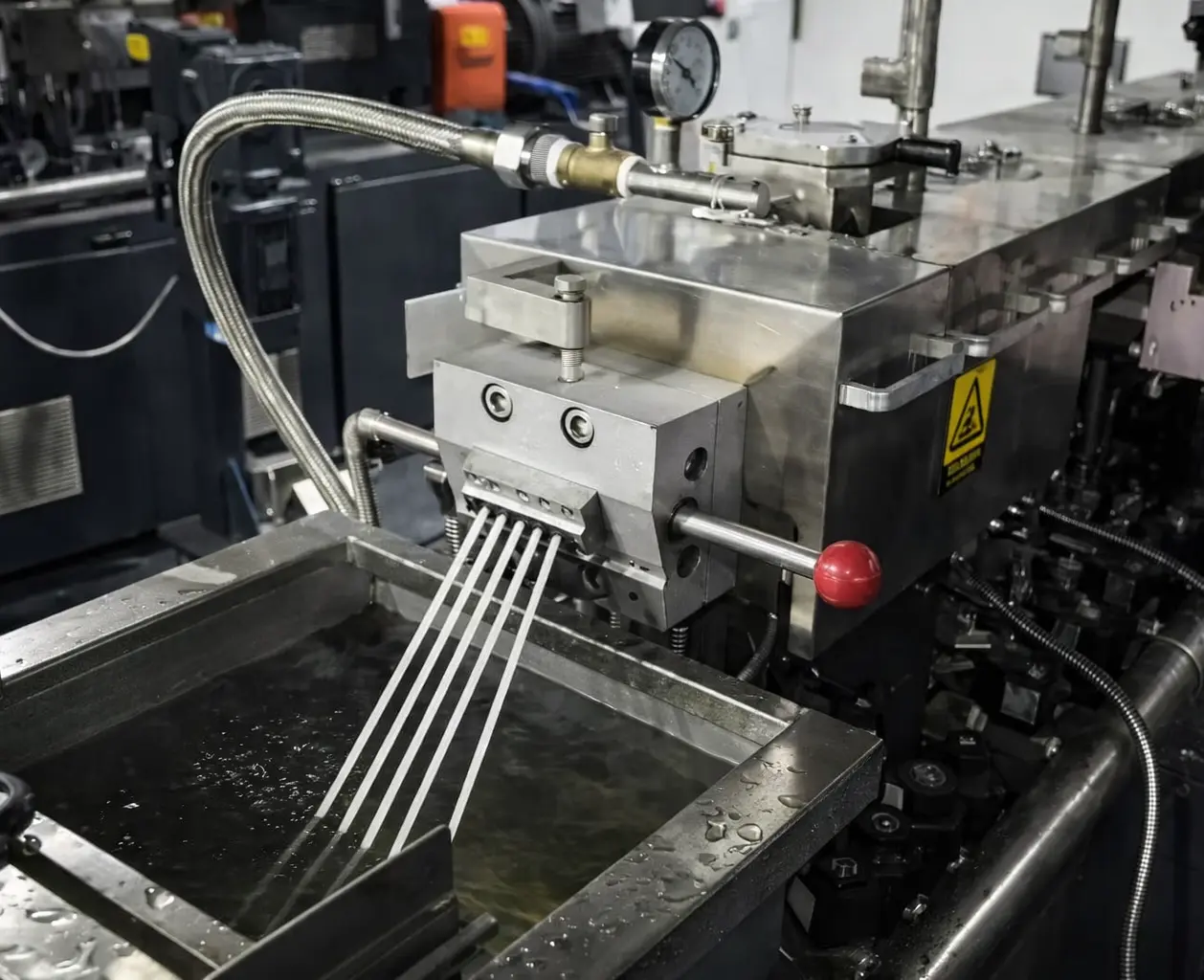

We operate twin-screw lines (Steer Engineering) with an annual capacity of 18,000 MT. This infrastructure ensures the precise dispersion required for high-quality masterbatches, guaranteeing consistent performance.

Leveraging 25+ years of industry experience, we support your specific needs through rapid custom colour matching and strict in-house QC. Full regulatory adherence is assured, with RoHS, REACH, and FDA compliance certificates available on request.